kayak design

Zusammen mit unserem langjährigen Partner Lettmann sind wir stolz auf das Ergebnis des 2018 auf der Messe Boot vorgestellten Mantas.

The new creeker from the traditional Moerser brand is doubly convincing. Because both performance and kayak design impress.

- Projekt: Kajak-Optimierung

- Kunde: Lettmann GmbH

- Leistungen: CAD-Optimierung, Visualisierung

- Webseite: lettmann.de

- Jahr: 2018

kayak design

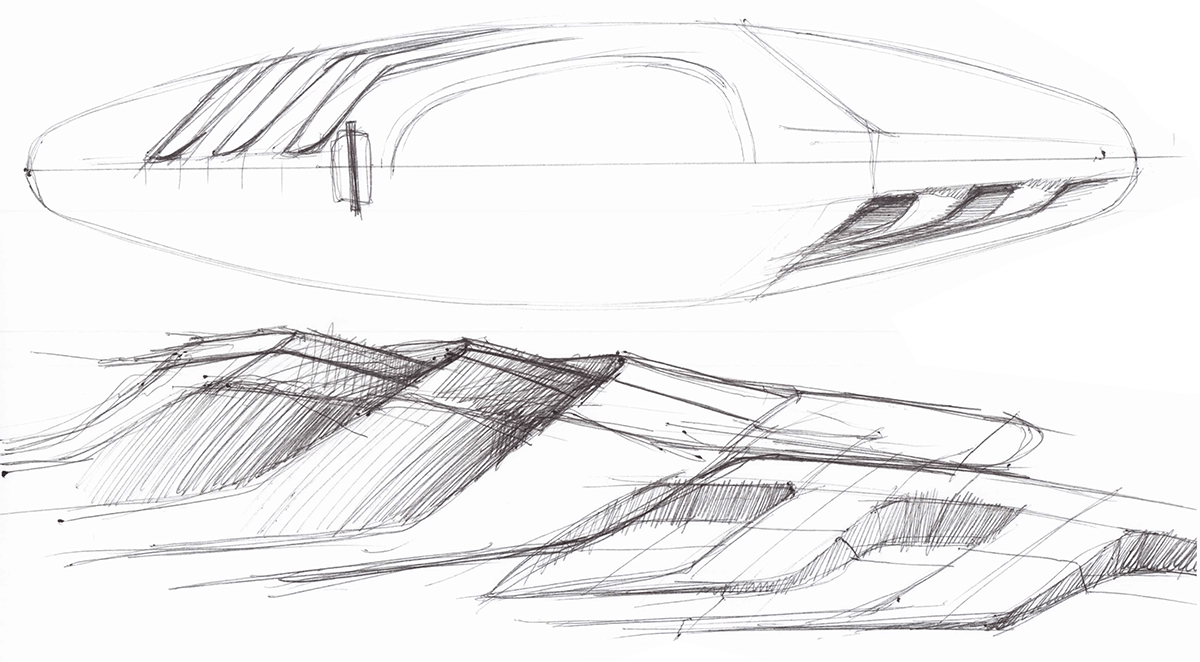

An der Unterseite der Wildwasserkajaks besteht aufgrund von hydrodynamischen Anforderungen wenig Gestaltungsspielraum.

Die Oberwasserseite hingegen konnten wir mit dem unverwechselbaren, modern interpretierten Lettmann-Look versehen.

Im Vergleich zur Granate wirkt der Manta schärfer gezeichnet. Die typischen Schwünge, Ecken und Kanten sind präzise herausgearbeitet und lassen keinen Zweifel an der Schnelligkeit und Zuverlässigkeit des Paddelbootes. Stufen und Hindernisse im Wasser sind somit kein Problem.

Das breite Heck garantiert ein schnelles und sicheres Auftauchen. Spoiler am Heck sorgen für eine hervorragende Beschleunigung.

Competence through many years of experience

In diesem Projekt haben wir an der Gestaltung des Oberschiffdesigns, der CAD-Umsetzung und der Werkzeugkonstruktion mitgewirkt.

Schnelle Entwicklung - exakte CAD-Umsetzung

Im Vergleich zu anderen Booten konnten wir die Produktentwicklung mithilfe von CAD-Umsetzung erheblich beschleunigen. Wurden die Boote früher noch manuell, in wochenlanger Handarbeit aus Schaumblöcken geschliffen, ist es heute schneller und vor allen Dingen präziser, die Daten am Computer zu erstellen. Auch Fehler, die sich erst im laufenden Prozess zeigen, sind auf diesem Weg schnell zu beheben.

Das spart Nerven, Zeit und Kosten.

Betreuung von A bis Z

We also supported the Lettman company with our in-depth knowledge and the delivery of 3D milling data during the subsequent tool design.

Die Boote werden aus Polyethylen in einem Rotationssinterverfahren hergestellt. Hierbei wird ein PE-Pulver in die Formen gefüllt. Diese zwei- oder mehrteiligen Formen werden in großen Öfen gleichmäßig erhitzt und rotieren auf zwei Achsen um sich selbst. Das schmelzende Material legt sich gleichmäßig als Wandung an die Werkzeugformen. Nach dem Abkühlen kommt das Entformen und finales Bearbeiten der Boote. Dank des drucklosen Verfahrens sind die Produkte nahezu spannungsfrei und somit extrem tolerant gegenüber Stoß und Druck. Das macht die Boote sicher und langlebig.

Compared to laminated tool molds, which are only made for small quantities or first prototypes, aluminum molds are more expensive to produce, but their durability is many times longer. In addition, they significantly improve the quality of the boats. The molds cool down more evenly and thus guarantee a controlled cooling process of the plastic. The result is lower deformation rates and increased product quality.

Die Boote werden aus Polyethylen in einem Rotationssinterverfahren hergestellt. Hierbei wird ein PE-Pulver in die Formen gefüllt. Diese zwei- oder mehrteiligen Formen werden in großen Öfen gleichmäßig erhitzt und rotieren auf zwei Achsen um sich selbst. Das schmelzende Material legt sich gleichmäßig als Wandung an die Werkzeugformen. Nach dem Abkühlen kommt das Entformen und finales Bearbeiten der Boote. Dank des drucklosen Verfahrens sind die Produkte nahezu spannungsfrei und somit extrem tolerant gegenüber Stoß und Druck. Das macht die Boote sicher und langlebig.

Compared to laminated tool molds, which are only made for small quantities or first prototypes, aluminum molds are more expensive to produce, but their durability is many times longer. In addition, they significantly improve the quality of the boats. The molds cool down more evenly and thus guarantee a controlled cooling process of the plastic. The result is lower deformation rates and increased product quality.

Wir mussten zwei Arten der Formerzeugung gegeneinander abwägen: CNC-Fräsen oder Gießen.

Gegossene Formen weisen in der Produktion schlechtere Oberflächenqualitäten auf. Die Oberfläche hat jedoch großen Einfluss auf das Fahrverhalten und die Optik der Boote – ein starkes Argument für CNC-gefräste Formen. Hinzu kam, dass ein händisch erzeugtes Modell des Bootes zwar vorlag, aber zugunsten der Genauigkeit ein zusätzliches Modell, basierend auf den digitalen Daten, hätte erzeugt werden müssen. Dank der CAD-Konstruktion konnte dieser Schritt übersprungen werden, denn die Daten der Negativformen konnten leicht digital erzeugt werden.

Ein italienischer Partner fräste die Werkzeughälften aus Vollaluminium-Blöcken. Dieser enorme Material- und Kostenaufwand zahlt sich jedoch in der späteren Herstellung aus. Dank der präzisen Formen kann der Manta serienmäßig und in großen Stückzahlen in der hauseigenen Produktion der Firma Lettmann hergestellt werden.

Ein italienischer Partner fräste die Werkzeughälften aus Vollaluminium-Blöcken. Dieser enorme Material- und Kostenaufwand zahlt sich jedoch in der späteren Herstellung aus. Dank der präzisen Formen kann der Manta serienmäßig und in großen Stückzahlen in der hauseigenen Produktion der Firma Lettmann hergestellt werden.