Design ist Arbeit und Arbeit muss gut organisiert sein

Unsere Methoden, Vorgehensweisen, Evaluierungs- und Qualitätssicherungswerkzeuge garantieren erfolgreiche und effiziente Projekte. Erfahren Sie mehr über unser Profil!

Erfolgsfaktor Design

Geben Sie Ihrer Marke eine Identität und heben Sie sich von der Konkurrenz ab.

Gutes Produktdesign schafft ein Image, das Emotion und Innovation gleichermaßen signalisiert. Beim Betrachten und Verwenden eines Produktes soll der Nutzer ein gutes Gefühl haben, das in Erinnerung bleibt. Sympathie und Einzigartigkeit, aber auch Zufriedenheit und Vertrauen sind Erfolgsfaktoren, die durch Design transportiert werden.

Aus diesen Gründen ist gutes Produktdesign immer schlüssig und durchdacht, benutzerfreundlich und nachhaltig und niemals willkürlich.

Als strategischer Wirtschaftsfaktor unterstreicht das Produktdesign die Sorgfalt, die ein Unternehmen in die Entwicklung seiner Produkte investiert. Denn Design macht die Qualität eines Produktes für den Nutzer sichtbar und erlebbar.

Sie interessieren sich dafür, wie Sie Design als Erfolgsfaktor nutzen können?

In unserem Artikel erhalten Sie dazu ausführliche Informationen, die anhand anschaulicher Beispiele erläutert werden.

Der Designprozess

Die frühe Einbindung von Design in Ihre Innovationsprozesse ermöglicht eine genaue und detaillierte Definition des Entwicklungsziels von Beginn an:

- Welches Problem soll das Produkt lösen?

- Welche Funktionen muss es dafür erfüllen?

- Welche Anforderungen stellt die Zielgruppe?

- Welche herstellungstechnischen, markenstrategischen und wirtschaftlichen Rahmenbedingungen sind zu berücksichtigen?

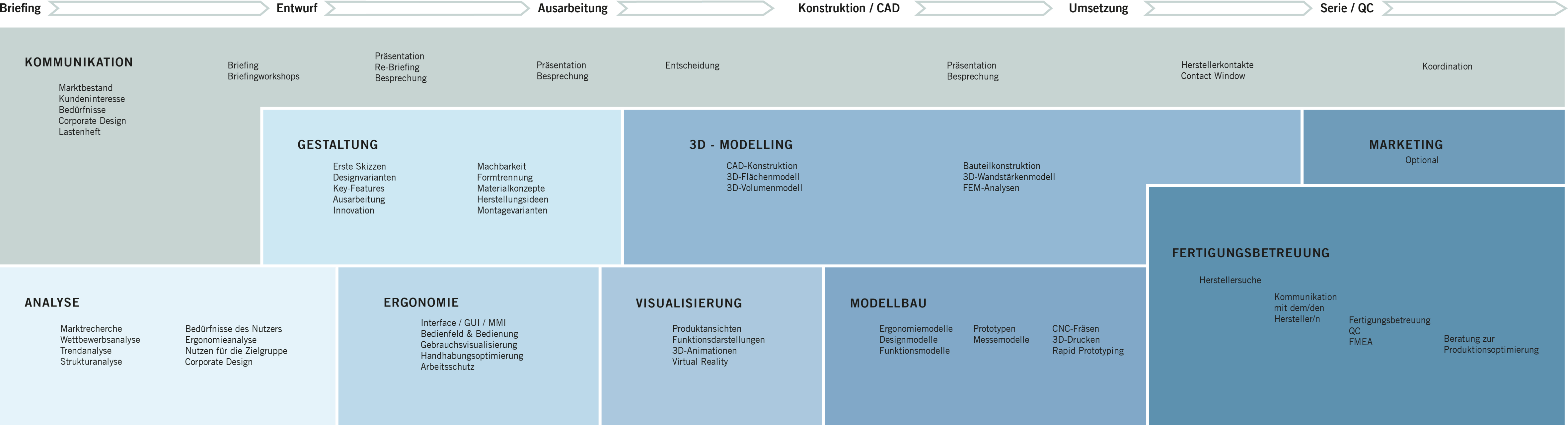

By weighting and combining the typical building blocks of a design development process differently, we can respond flexibly to each project with its individual requirements.

In the following you can see a typical and exemplary project process in chronological and weighted order.

Building blocks of a design development

The two building blocks "Communication" and "Analysis" form the cornerstones of our design development. Communication runs like a red thread through the entire project process. The various possible project participants such as clients, designers, manufacturers, engineers or customers are in an intensive exchange of information.

A detailed analysis creates the intellectual and technical basis for our examination of a product. The competitive situation, patents, specific expertise, technical framework conditions, needs and requirements of users as well as manufacturers and designers are compiled and evaluated.

The collected and filtered information flows into the creative design process. Concepts and initial ideas are developed and repeatedly checked for the requirements of the manufacturer and target group. In the further course, the elaboration of well-founded designs takes place.

The optimization of its ergonomics goes hand in hand with the design of the product. Because the intelligent adaptation of innovative technology to people is the prerequisite for success in competition. Products that explain themselves to people through intuitive user guidance create safety and efficiency in use.

Throughout the entire development process, visualizations are an important means of presenting the developed concepts or ideas to our clients, marketing, designers, customers or investors and of supporting decision-making processes. This is done in graphic and digital form.

Modern and efficient product development is no longer conceivable today without the use of 3D modeling systems. Solidworks and Rhinoceros 3D enable us to design for production and guarantee simple and flexible data exchange with our partners for further processing up to series production.

Model building is an important means of verifying various steps in the development process. Roughly speaking, models are used to estimate volume or proportions. CNC-milled, they enable us to precisely check 3D CAD data sets and the functionality of technical solutions. Design models with a surface finish are often more convincing at customer or trade fair presentations than any image.

Even after the design development has been completed, we ensure in production support that the end product, which will later be manufactured industrially, keeps the brand promise. Strict quality control ensures that the finished product conforms to previous development work and customer requirements.

In our article “Think like a product designer“ find out more about our working methods and methods.

Unser definiertes Ziel: Ihnen als Kunden das bestmögliche Produkt zu liefern.

Methods

A wide variety of methods are used to find out the specific needs of the users of a product:

- user surveysto find out problems or requests from users

- Axis Charts (Morphological box) to classify properties/similarities or relationships

- brainstorming/-writing to generate and further develop ideas

- Action Analysis, user analysis, usability testing, usability studies to detect weaknesses in usability

- mood boards, to visualize user worlds, moods or aesthetic qualities

- benchmarking, competition investigations

- prototyping, rapid prototyping, preliminary models

But the requirements of the manufacturer must not be ignored either.

- Production-ready construction, Analysis of the structural design in order to identify possibilities for simplification and thus cost reduction

- Production-oriented use of materials taking into account the required physical properties as well as wear and fatigue strength

- Appropriate for the purpose and the optical requirements material selection and processing methods