cooperation projects

Collux ZIM project funding

This project was Central Innovation Program for SMEs (ZIM) promoted. The ZIM is a nationwide funding program that is open to all technologies and sectors, with the aim of sustainably strengthening the innovative power and thus the competitiveness of medium-sized companies. The technological innovation content and good market opportunities of the funded R&D projects are essential for approval (https://www.zim.de/ZIM/Redaktion/DE/Article/ueber-zim.html).

Nanopartikel in der Industrie: Herstellung und Einsatzgebiete

Colloidal nanoparticles are tiny particles that are very finely distributed in water or other solvents. With the help of a laser beam, the smallest parts are vaporized from the surface of a solid and bound in a liquid medium. They are usually very expensive: gold nanoparticles cost about 300 times more than the pure precious metal in the same quantity in one piece. There are almost no areas of industry and research in which nanotechnology is not used. The areas of application range from chemistry and materials engineering to biotechnology, pharmacy and medical technology to energy generation, energy storage and environmental protection.

A spin-off of the Projekter was aimed at right from the start. In this way, knowledge transfer from the university environment to industry could be ensured. Due to the development, which was ultimately patent pending, and the successful cooperation, the project came closer and closer. The goal is the spin-off at the beginning of 2022 (https://www.uni-due.de/2020-06-29-nanoparticle-on-button-pressure).

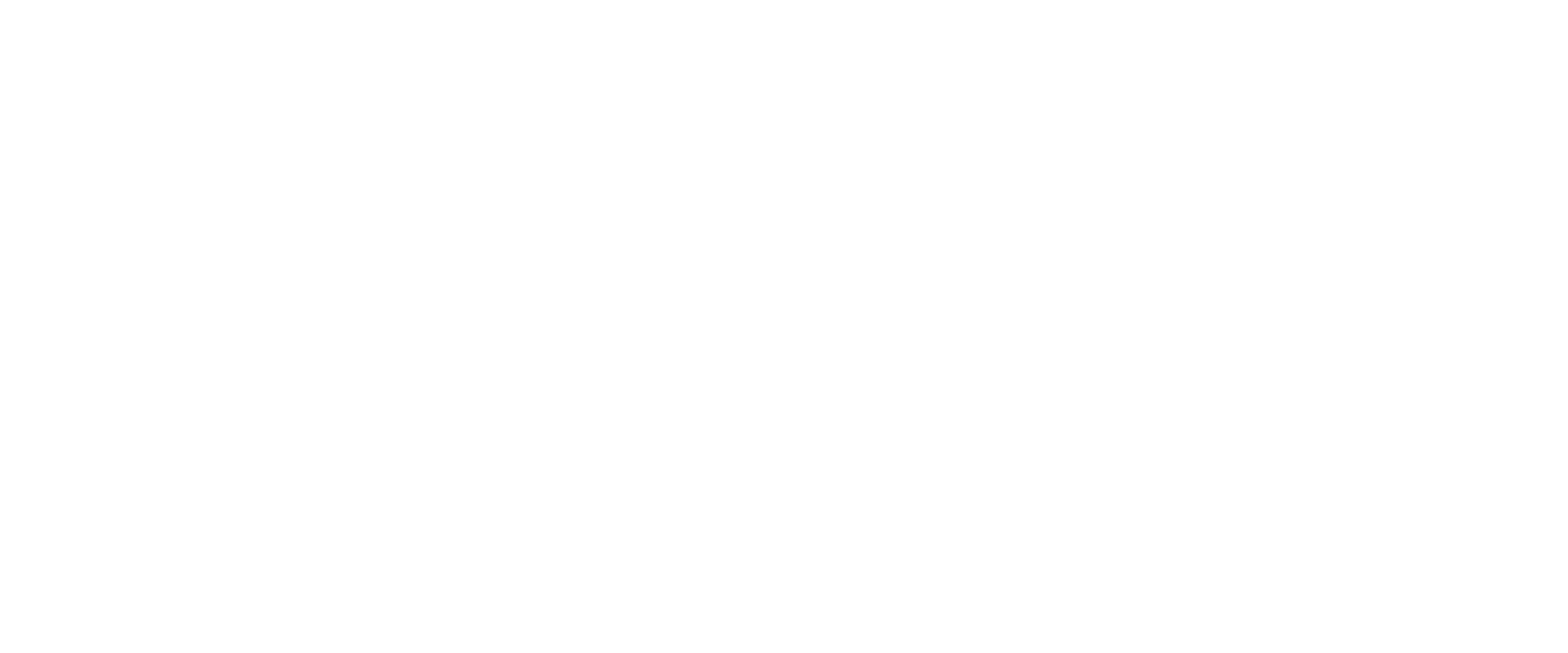

Division of work areas

CryLaS GmbH wählte das passende Lasersystem aus und arbeitete das elektrische System aus, während die Universität Duisburg-Essen für die prozesstechnischen Grundlagen und die Gesamtintegration des Automaten verantwortlich war.

Our scope of duties included product/design development, device ergonomics, housing construction and industrialization of the prototype as well as presentation creation.

The specification

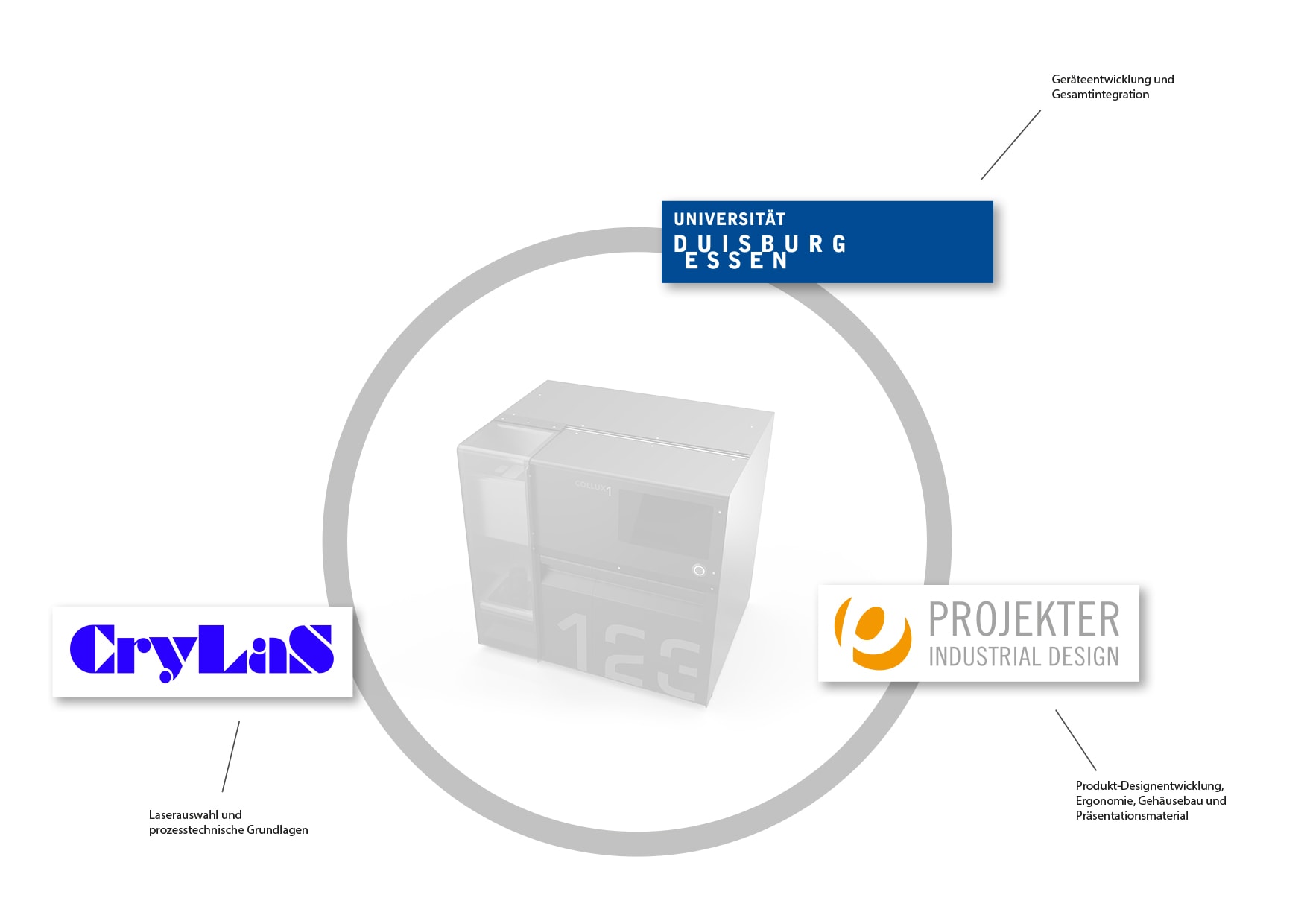

Im August 2018 starteten wir das Projekt mit einer umfassenden Markt- und Umfeldanalyse. Als Grundstein für innovative Produktentwicklung konnten wir die Anforderungen an das Gerät mit den Projektpartnern erarbeiten und fassten die Ergebnisse in einem gemeinsamen Lastenheft zusammen. Dies umfasste ergonomische Ansprüche, formale Kriterien, Umgebungsfaktoren, technische Anforderungen, Herstellbarkeit und Produktionskosten.

Ziel war es, ein zeitloses Design und die richtige Produktsemantik zu schaffen, um eine langfristige Verfügbarkeit der Laborgeräte zu gewährleisten. Die Gestaltung musste unter Berücksichtigung einer zum Markteintritt kleineren Serie erfolgen.

project flow

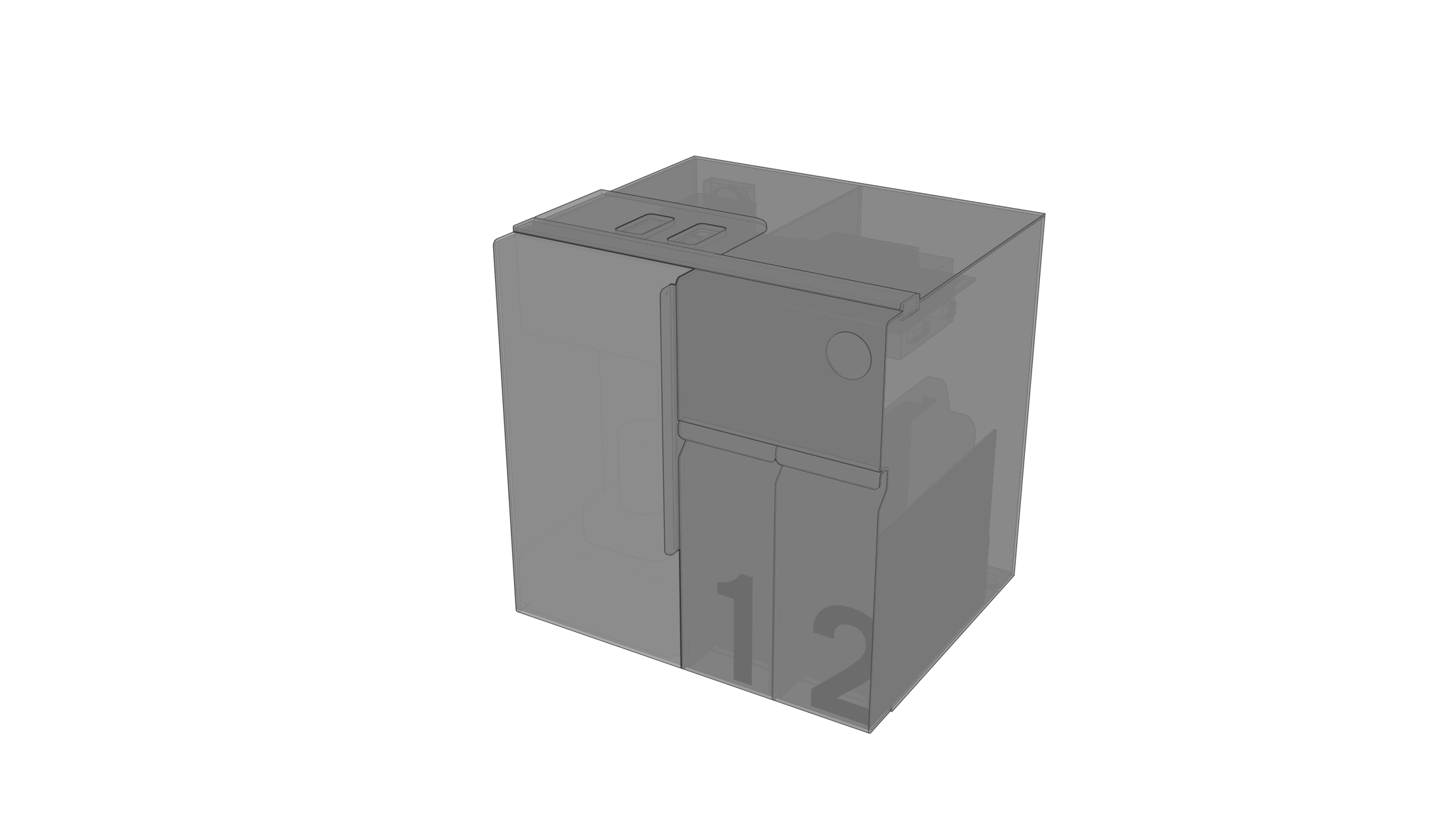

Das Team der Universität und die Firma CryLaS erarbeiteten ein mögliches Technologiepaket, bestehend aus optischen und elektronischen Komponenten, das die Mindestmaße des Gehäuses definierte. Für den Aufbau des Automaten galt: je kompakter das Gehäuse, desto kostengünstiger und integrierbarer ist das Gerät bei der Fertigung und im Einsatz.

Konzeption und Ergonomie des Nanovollautomaten

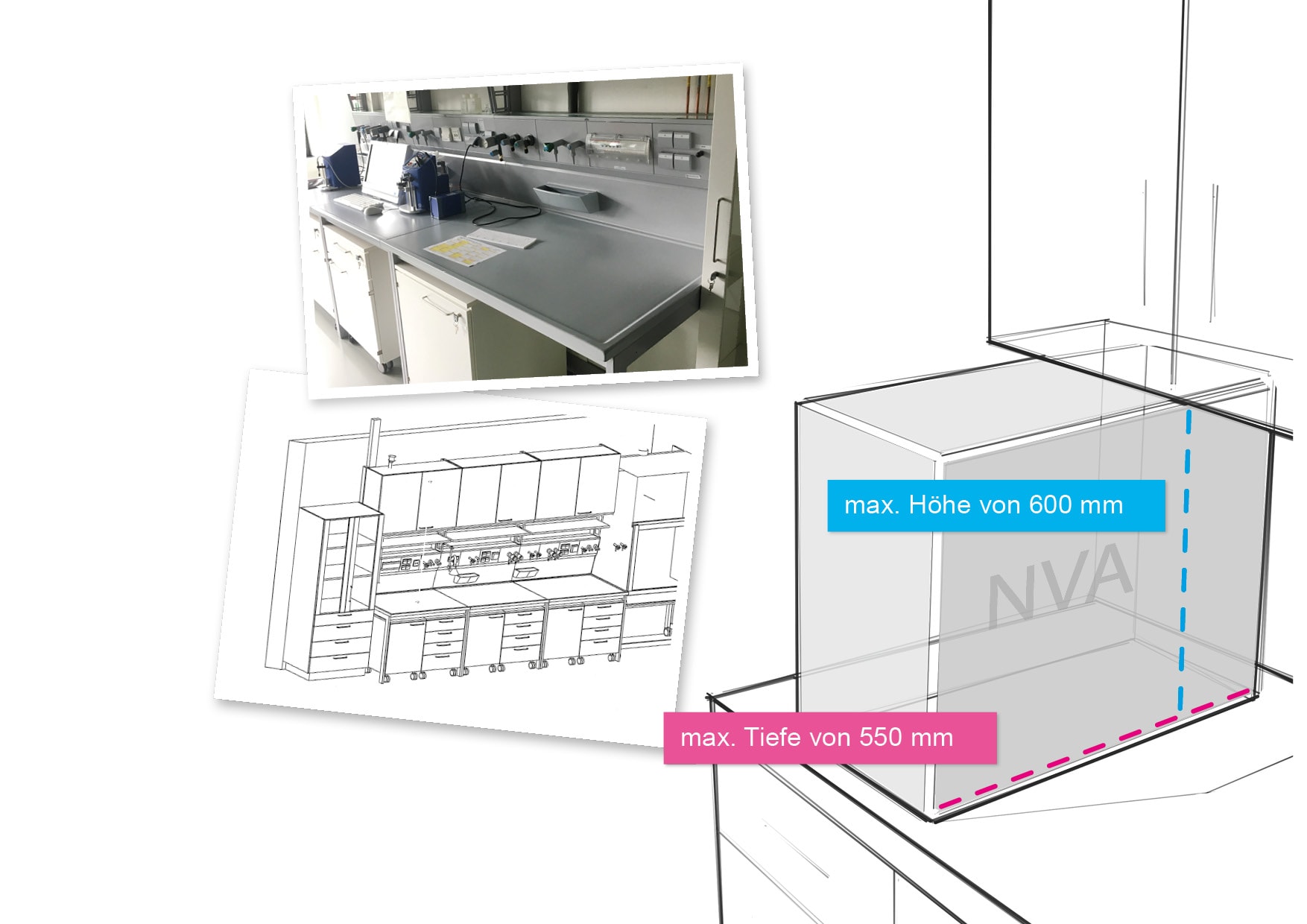

It was determined that the nanocolloids should be produced with the highest possible purity. The starting materials should be three precious metals (gold, silver and platinum) and a colloid medium (fluid).

So we needed both an exchangeable material cartridge and three liquid containers, because in addition to the fluid we also needed a container for the liquid to flush the system and a stabilizer solution.

In addition, a release quantity was defined as a measure for the intended collection vessel.

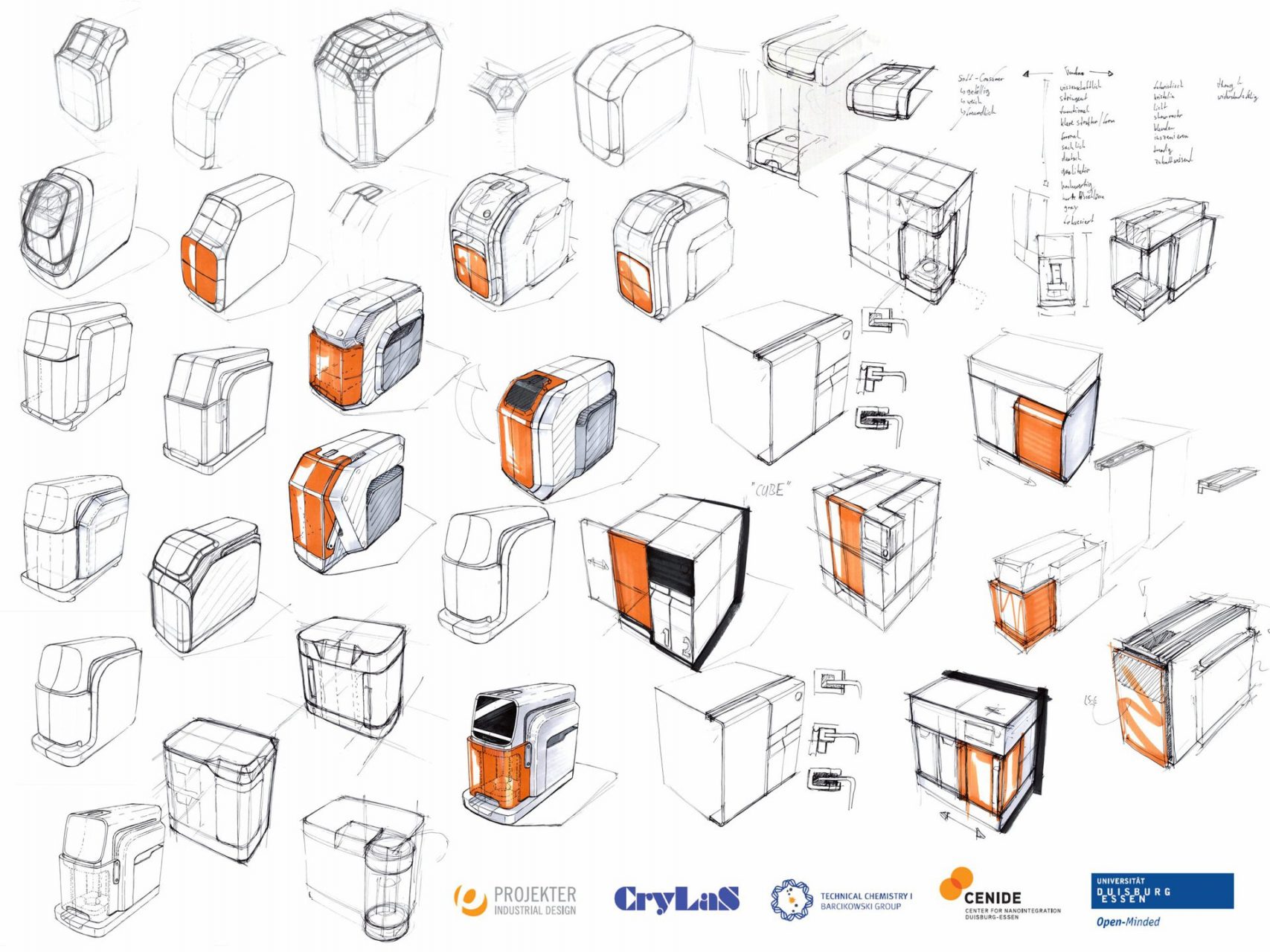

While the University of Duisburg-Essen and CryLas were conducting various series of tests to determine the prerequisites for optimal productivity of the ablation (process of colloid creation), we created the first ergonomic and topology concepts based on the key data known at the time.

For this purpose, the questions had to be answered beforehand as to which functions the machine has and which requirements must be met in the area of conflict between users, environment and technology.

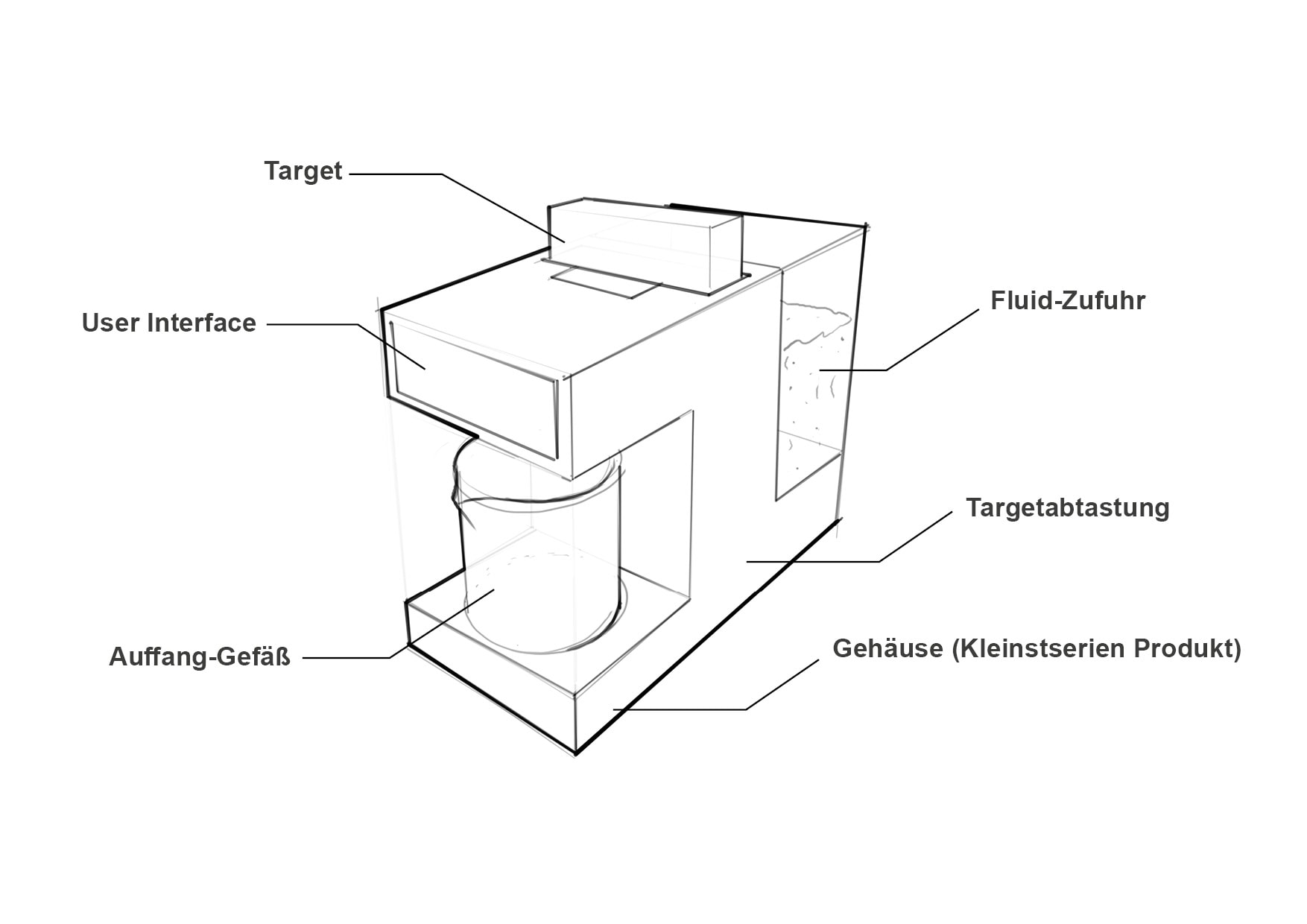

The following subject areas could be defined by the schematic drawing of the nano-automatic machine:

- fluid delivery

- Target

- UI

- collection vessel

- inner workings

- housing construction.

In this way, it was possible to determine which factors were set and for which sub-areas new concepts were required.

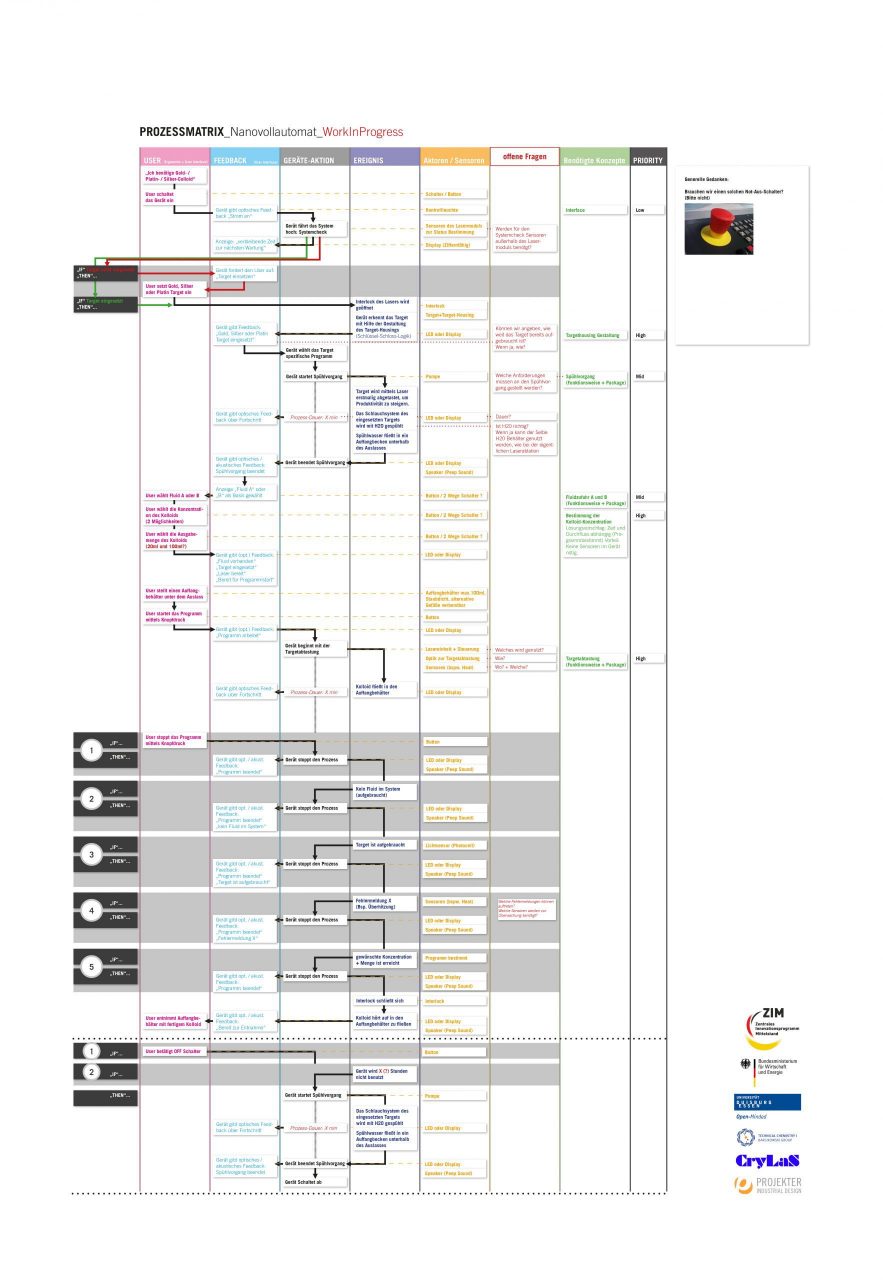

To support this, we created a process matrix. With the help of the plan, we were not only able to simulate a detailed course of action for the user, but also to disclose weak points and potential risks in the process.

In order to ensure good device ergonomics, a particular focus was on investigating the interaction points between humans and the device. As a result, we were able to define areas of action. These include operation via the digital interface, filling and replacing the fluid tanks, inserting or replacing the target housing and removing the finished precious metal colloid.

Konzeption, Entwicklung und Test der Gerätetechnologie

Durch Übertragung der Auswurfmechanik einer Nintendo 64 Konsole haben wir einfache und robuste Bedienkonzepte erarbeiten können.

In order to check ergonomics and function, we made mockups of three favorite construction variants. At this early stage of the process and in the development of these ergonomic concepts, the "design" in the sense of an aesthetic, external design did not play a role. It is important that the functionality of a device is guaranteed first, so that the aesthetics can then be matched to the function.

We had the resulting models tested and commented on by potential users in the product environment over a longer period of time. This allowed us to correct errors through early testing phases and ensure that our concepts worked in the field test.

Unsere Werkstatt-Infrastruktur erwies sich auch in diesem Projekt als notwendig und hilfreich. Wir entwickelten eine entnehmbare Materialkassette, die wir in unserem hauseigenen 3D-Labor mittels 3D-Druck anfertigten. Wir stellten die Kassette der Universität zur Verfügung, um sie auf Funktion und Dichtheit in den Versuchsreihen zu überprüfen und in Verbindung mit unserer entwickelten Auswurfmechanik zu testen.

"How can we imagine the case?"

We developed a design for the machine that was aesthetic, based on ergonomic knowledge, met all safety requirements and was easy to implement according to the production method.

The small series of 20-500 pieces required production methods without expensive mold or jig construction. Here it became clear once again that no compromises in design are necessary, even with major restrictions in terms of manufacturing options. Since we have already worked successfully on projects with similar issues in the past, we were able to draw on our experience in the field of design with bent sheet metal and folded parts.

Unter Berücksichtigung des Anforderungskataloges entstanden zwei Design-Varianten. Eine Variante überzeugte durch ihre minimale Stellfläche, wohingegen die andere Variante die frontale Bedienung als zentrales Merkmal der Gestaltung zu Grunde lag. Diese wurden in einem Projekttreffen vorgestellt und diskutiert. Hauptunterschied besteht in der Verortung der beiden Fluidbehälter. Die Variante „easy front Access“ überzeugte alle Projektpartner einstimmig in Handhabung und Gestaltungpotentialen.

Iteration loops are part of our everyday life

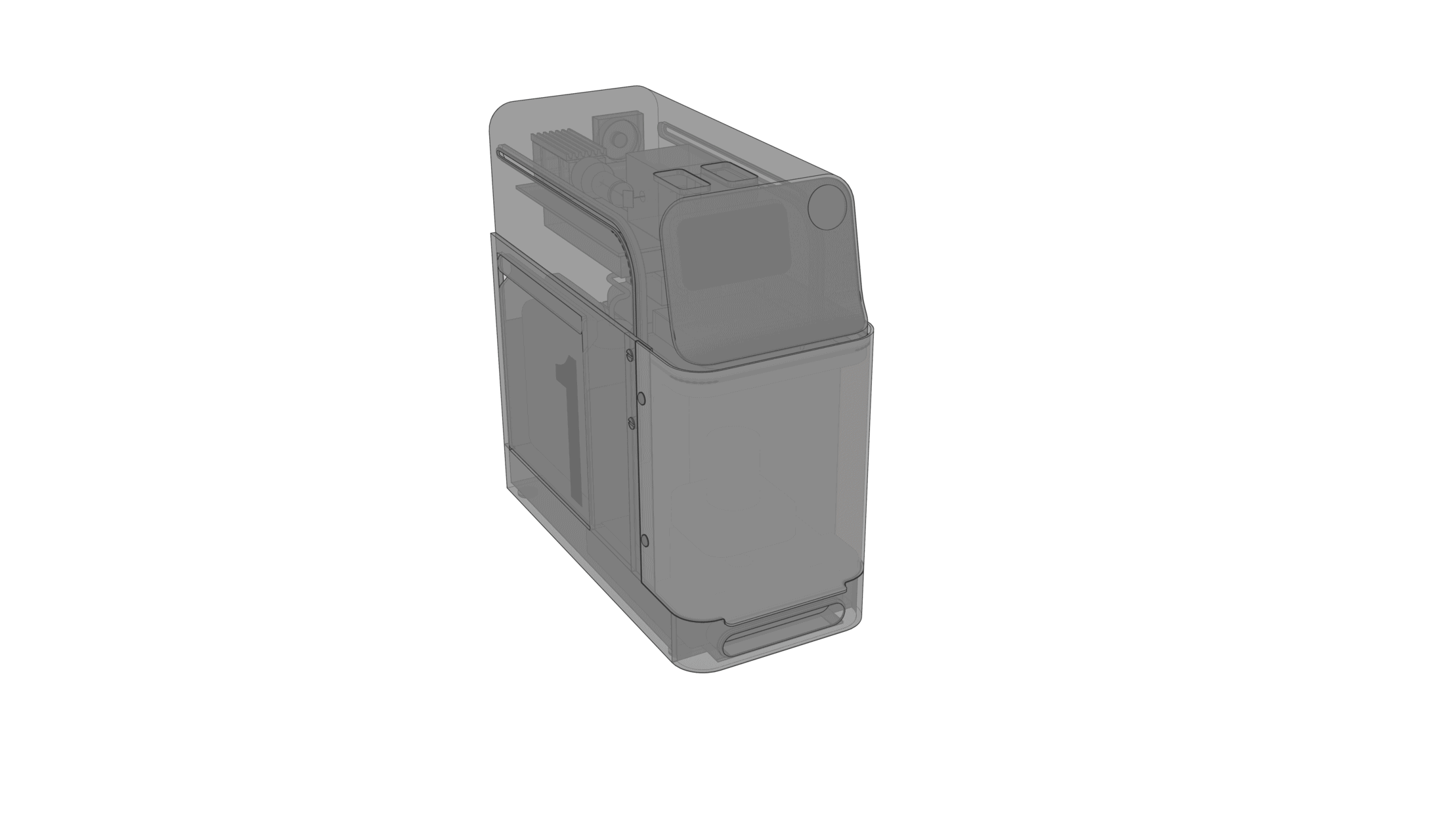

Da das bisherige Lasersystem nicht leistungsfähig genug war und in dieser Konfiguration nicht konkurrenzfähig auf dem Markt gewesen wäre, musste eine stärkere Laserstrahlquelle verwendet und erneut getestet werden. Das alternative Lasersystem erbrachte schließlich die gewünschte Produktivität. In der Konsequenz musste die Gerätetopologie überarbeitet und somit auch das Design bzw. das CAD dem neuen, größeren Bauraum der Technik angepasst werden.

Correction loops are part of the development process and are valuable in early phases, since there is still the opportunity to implement them without great expense. These types of adjustments and optimizations are also part of our day-to-day business in other projects.

Insbesondere der Aspekt einer möglichen Skalierung, der bereits bei der Bewertung der beiden Designvarianten diskutiert wurde, erwies sich nun als großer Vorteil. So war die Anpassung umsetzbar, ohne den Charakter und den ursprünglichen Designgedanken des Automaten zu ändern.

prototyping

Our final work package consisted of putting the developed design in our prototype workshop umzusetzen. Das Gehäuse im Prototypenstadium kann zu 100% zurück gebaut werden, um nachträgliche Änderungen durchführen zu können. So wurde beispielsweise an Stelle von dauerhaften Schweißverbindungen vorerst auf Verschraubungen der Gehäuseteile gesetzt. Später, in der Serienfertigung, können diverse Schraubverbindungen durch Schweißstellen ersetzt werden, wodurch der Montageaufwand und die Produktionskosten weiter reduziert werden. Nach Erhalt der extern gefertigten Gehäuseteile, welche zuvor von uns in CAD konstruiert wurden, konnten wir mit der Montage des funktionsfähigen Prototypen starten. Aus Blechbiege- und Kantteilen, milled parts , screws and 3D printed parts , through painting, assembly and pasting with product graphics, the first two nano fully automatic machines were created step by step.

The conclusion of the project was the insertion of the mounting plate with the laser system and the connection of the housing and the technical unit.

The result is two functional prototypes that, as planned, can be used to present the project idea at trade fairs or similar events and for initial field tests.

The result

Wir erachten den Transfer von Wissen und innovativen Forschungsergebnissen aus den akademischen Bereichen in die Industrie als besonders wichtig. Deshalb sind wir stolz, Teil der Kooperation sein zu können und als Innovationstreiber und umsetzungsorientierte Partner, Ideen wirtschaftlich in den Markt zu bringen. Wir halfen nicht nur bei der Formfindung des Automatengehäuses und dessen Ergonomie, sondern leisteten auch bei der Prozessoptimierung zur Erstellung des Kolloides unseren Beitrag. Das erklärte Ziel der Ausgründung ist für das Jahr 2022 geplant. Hierfür wünschen wir viel Erfolg und freuen uns, dass wir das junge Start-Up auch weiterhin als Design- und Entwicklungspartner begleiten werden.