Neuartige Kettenführung

Component reduction - from 7 make 1

- Projekt: Kettenführung für Mountainbike

- Kunde: B-Labs

- Leistungen: Optimierung des Produktdesigns, CAD-Konstruktion, Visualisierung

- Award: 2015 DESIGN & INNOVATION AWARD

- Jahr: 2014

How do we design a successful product that is even easier to use, lighter, more versatile, more stable and cheaper?

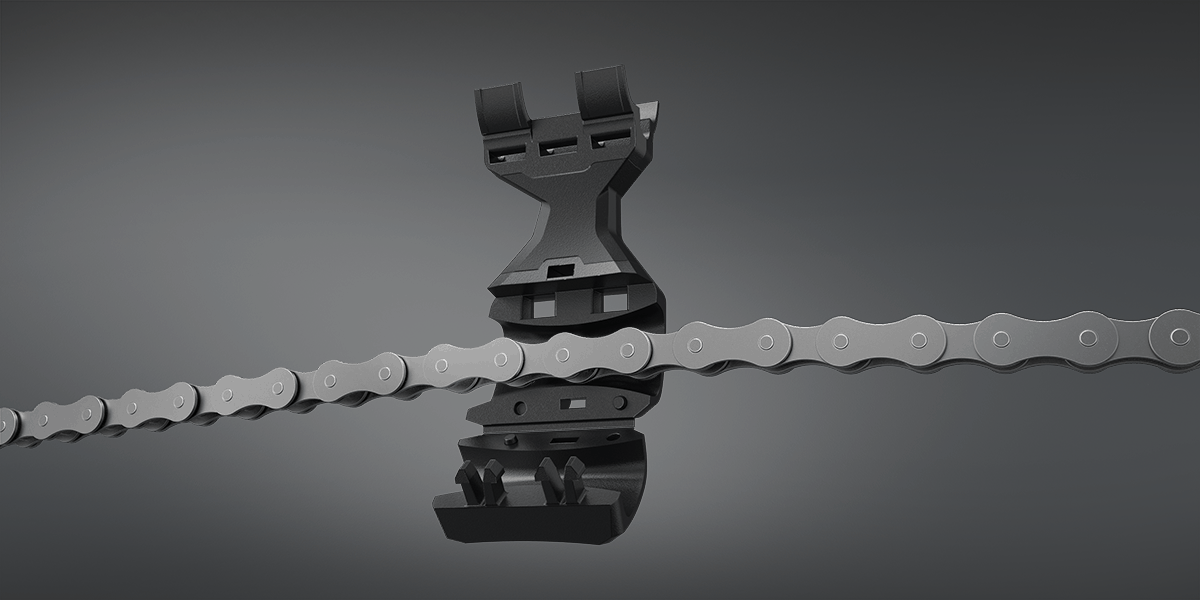

In tough off-road use, the chain of a mountain bike is exposed to extremely strong vibrations. In order to prevent it from jumping off the sprocket or chain ring, the chain is tensioned and held in position by a so-called chain guide, especially in enduro and downhill use.

Die c.guide eco ist in Zusammenarbeit mit der Fahrradentwicklungsfirma B-Labs aus Biel in der Schweiz als Weiterentwicklung der erfolgreichen c.guide V02 entstanden. Zum Ausgleich der unterschiedlichen Positionen der Kette beim Schaltvorgang bietet die alte Kettenführung zwei Bewegungsachsen. Sie besteht aus zwei Aluminium-Druckgussteilen, vier verschiedenen Kunststoffspritzgussteilen und einer Schraube.

- Projekt: Kettenführung für Mountainbike

- Kunde: B-Labs

- Leistungen: Optimierung des Produktdesigns, CAD-Konstruktion, Visualisierung

- Award: DESIGN & INNOVATION AWARD 2015

- Jahr: 2014

Ziele unserer Neuentwicklung

- Improvement of mounting on the bicycle frame

- Reduction of production costs

- weight reduction

- Reduction of chain friction

Our work began with the analysis and breakdown of the requirements into their individual components.

What is the best way to solve each problem?

By realigning the design and turning away from the use of previously used aluminum components, a completely new type of chain guide was created at the end of the design development.

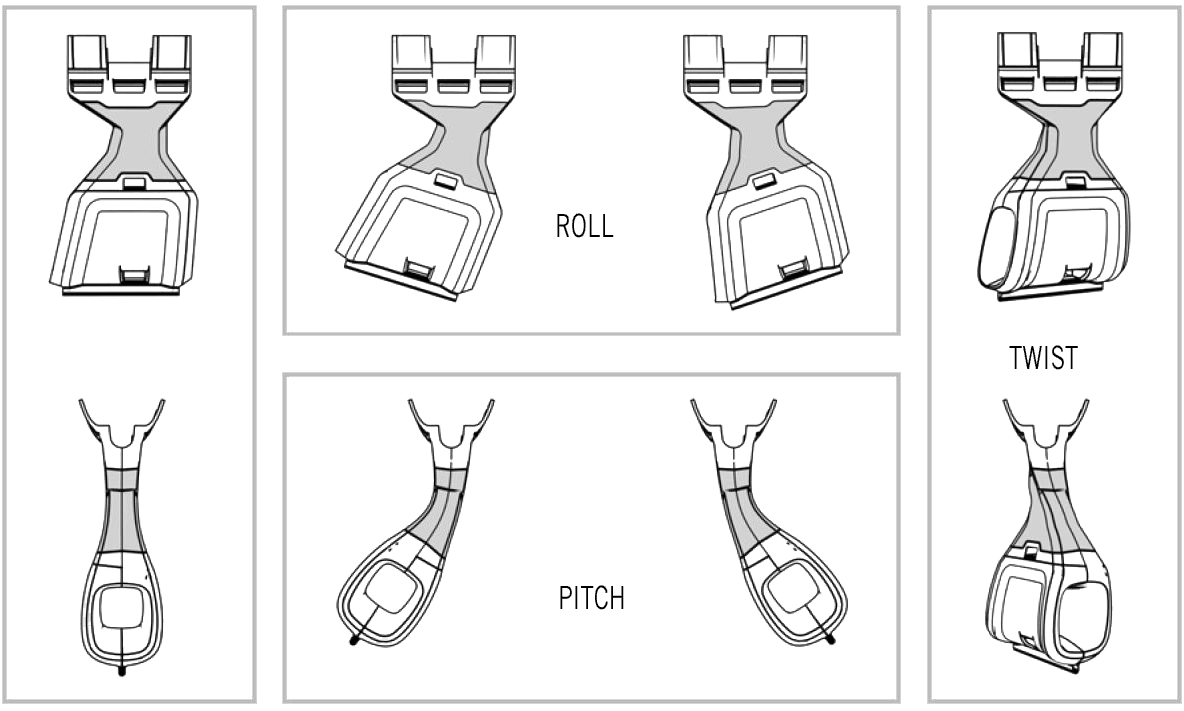

In addition to the required changes, we were able to increase the durability of the product by reducing the components to a single two-component injection molded part. At the same time, it was possible to reduce production costs many times over. The rigid upper part fixes the c.guide eco securely to the bicycle frame. The flexible center shaft made of a thermoplastic elastomer holds the chain guide sleeve in position and allows the chain to be stabilized and at the same time almost silently dampened in three movement axes.

The result of the design development is the lightest and at the same time most flexible chain guide in the world.

Eigenschaften der neuartigen Kettenführung c.guide eco:

- fast, tool-free and safe assembly due to one-piece construction

- Reduction of the production costs by a multiple

- Weight reduction by 22% (14 gr.)

- Greater flexibility thanks to 3 axes of movement – resulting in less chain friction

- less chain noise

- better shiftability of the chain

- less chain wear

- excellent cushioning properties

- better durability under continuous load

- no impairment of function due to dirt

- Suitable for 1-/2-/3-speed crank sets due to the great freedom of movement

Unser Fazit

Proven technology can also be improved.

It's always worth thinking outside the box and rethinking supposedly proven materials and constructions.

Product design is not about improving a product across the board, but about solving the many individual problems of the user and the manufacturer.

By reducing 7 components to just one, we have significantly improved an already good product.