Generative Design

Algorithms & Design

Algorithms, parameters, functions….

Are we still talking about design or did we accidentally end up in the advanced math course?

The answer is: BOTH.

Find out what generative design is, what the advantages are and to what extent it is forward-looking.

Keep your finger on the pulse with us!

Benefit from our know-how about generative design!

Use new technologies!

Develop or optimize your innovative, award-winning product with us!

We generate a large number of variants for you in the shortest possible time.

Define parameters

The classic type of design, in which an idea is implemented by the designer with his analogue means, is increasingly receding into the background.

With generative design, we use parameters that we define and influence together with you.

We are familiar with parameters in scientific fields: they are numerical values that describe a property.

In the design we also find parameters that have to be considered in the design and that define a product.

At the beginning of the design of a new product, we work with you to develop a catalog of requirements in which we define values.

A simple example of a numerical indication of value is the maximum dimensions of a product.

With the help of parametric design programs like the ones we use, not only can the maximum dimensions be determined, but the shape of a body can also be determined.

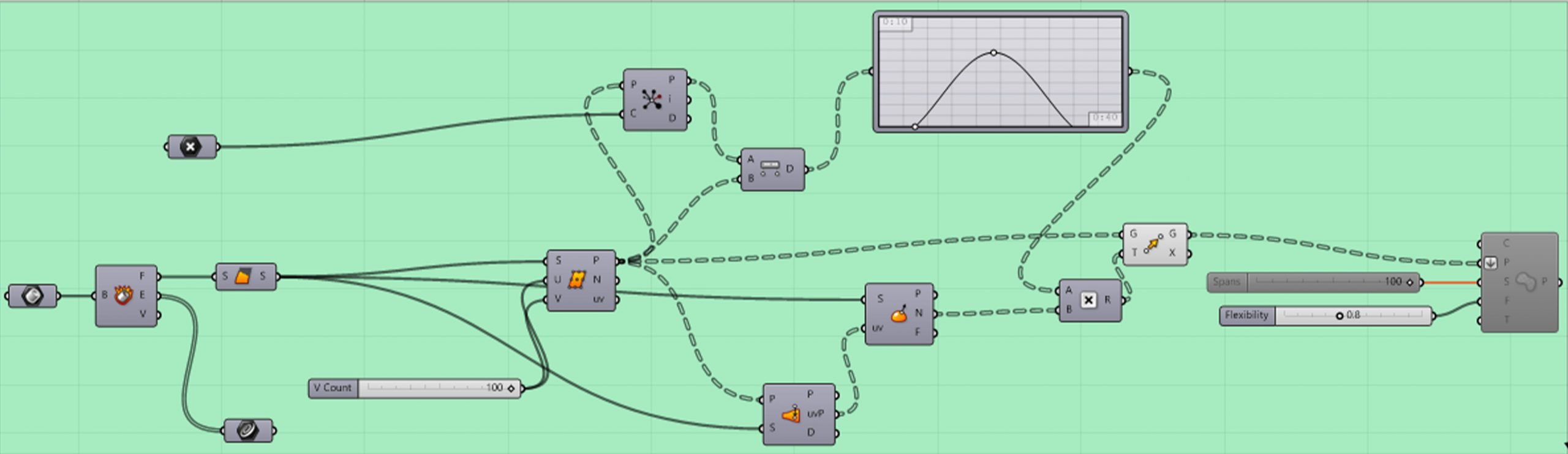

Parametric design

We design your products in three-dimensional space. A point in this space is determined using the xyz values of a coordinate system and can be moved in space by changing the numerical value of the coordinates.

If two more points are added in space and connected by lines, a surface is created. If another point is added and connected to the other points, further surfaces are created.

A body has been generated, defined by the previously determined points. If the body does not show the desired shape, the points can be changed later.

Use modern technologies

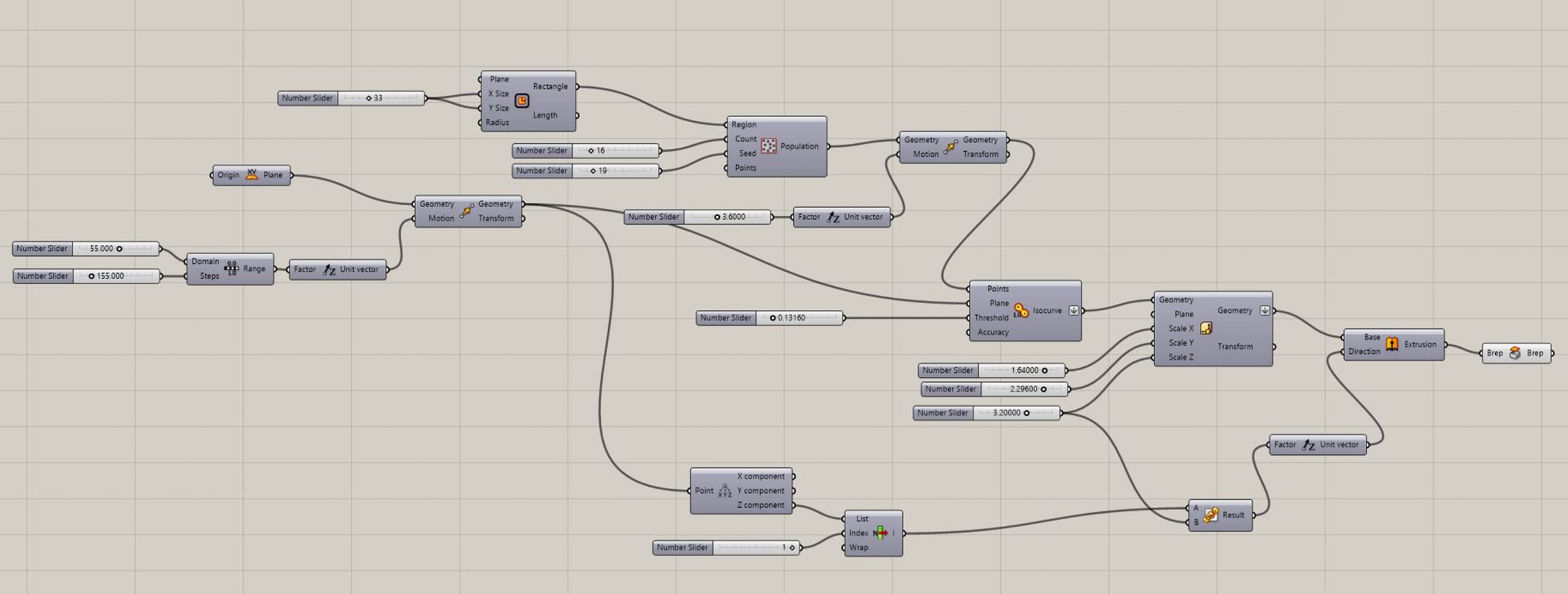

With the help of functional equations that build on one another, points can be arranged in space in a much more complex manner, which means that not only straight-line surfaces can arise, but also surfaces that span multiple times.

Without such functional equations and without modern 3D programs, such as those used by engineers, the components created in this way can only be realized with great effort, let alone changed later.

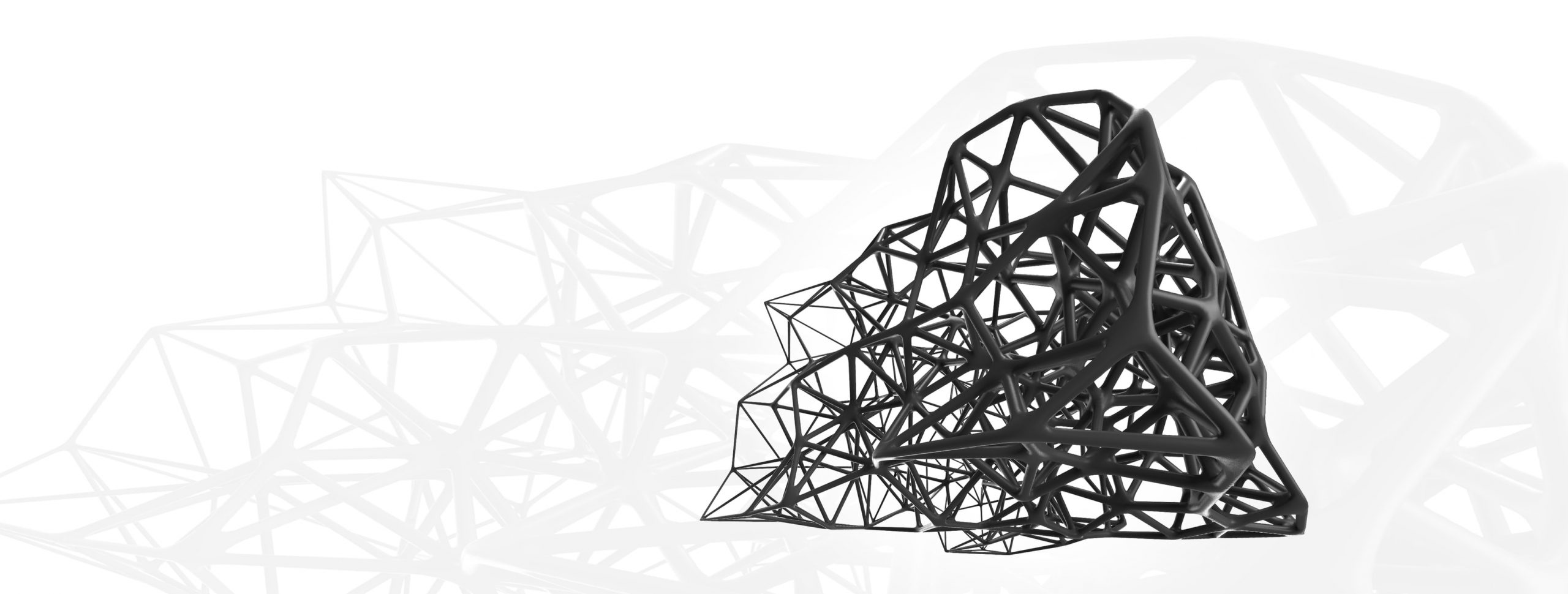

The algorithms used are based on mathematical laws and the model of nature.

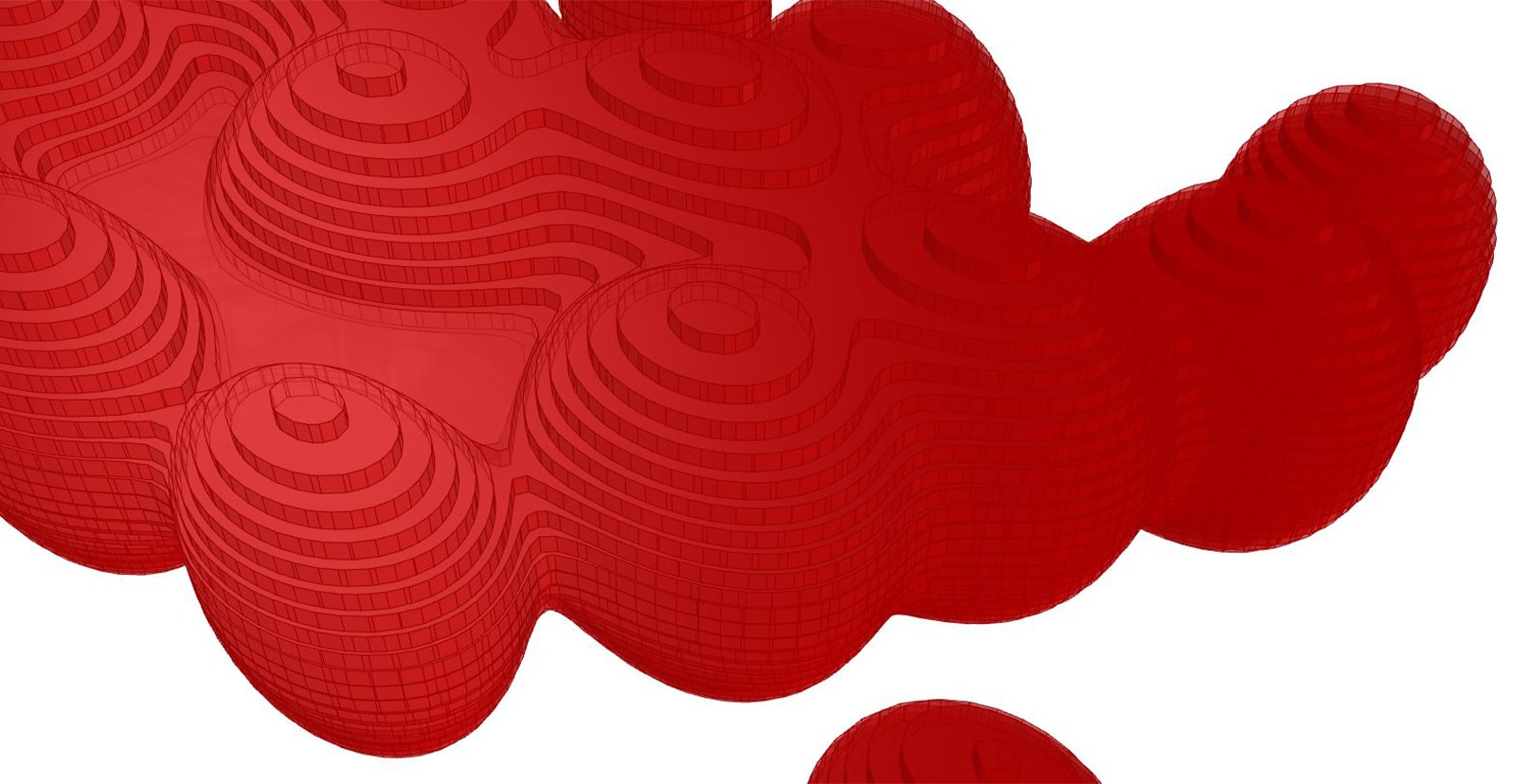

For example, when generating a particularly light but also stable component, forms that appear organic can be created as desired.

Conventional manufacturing processes, such as injection molding or CNC machining, quickly reach their limits with such shapes. With these classic processes, we have to comply with design rules that restrict us in finding the right form.

The implementation of the generatively generated design enables us to use new additive manufacturing processes. It is probably the most promising and fastest developing branch of manufacturing processes.

Even today, series components are made of plastic, ceramic or metal using 3D printing.

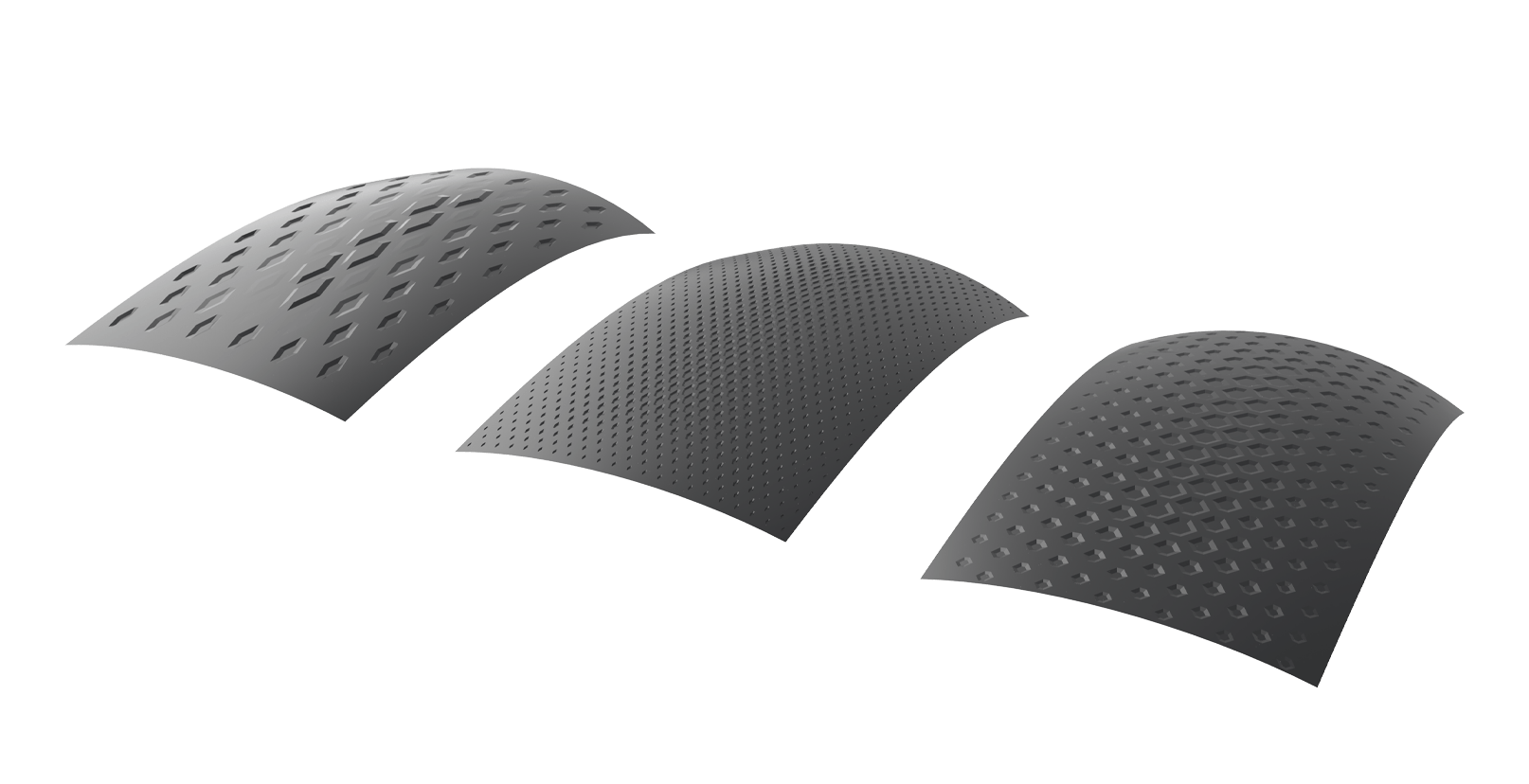

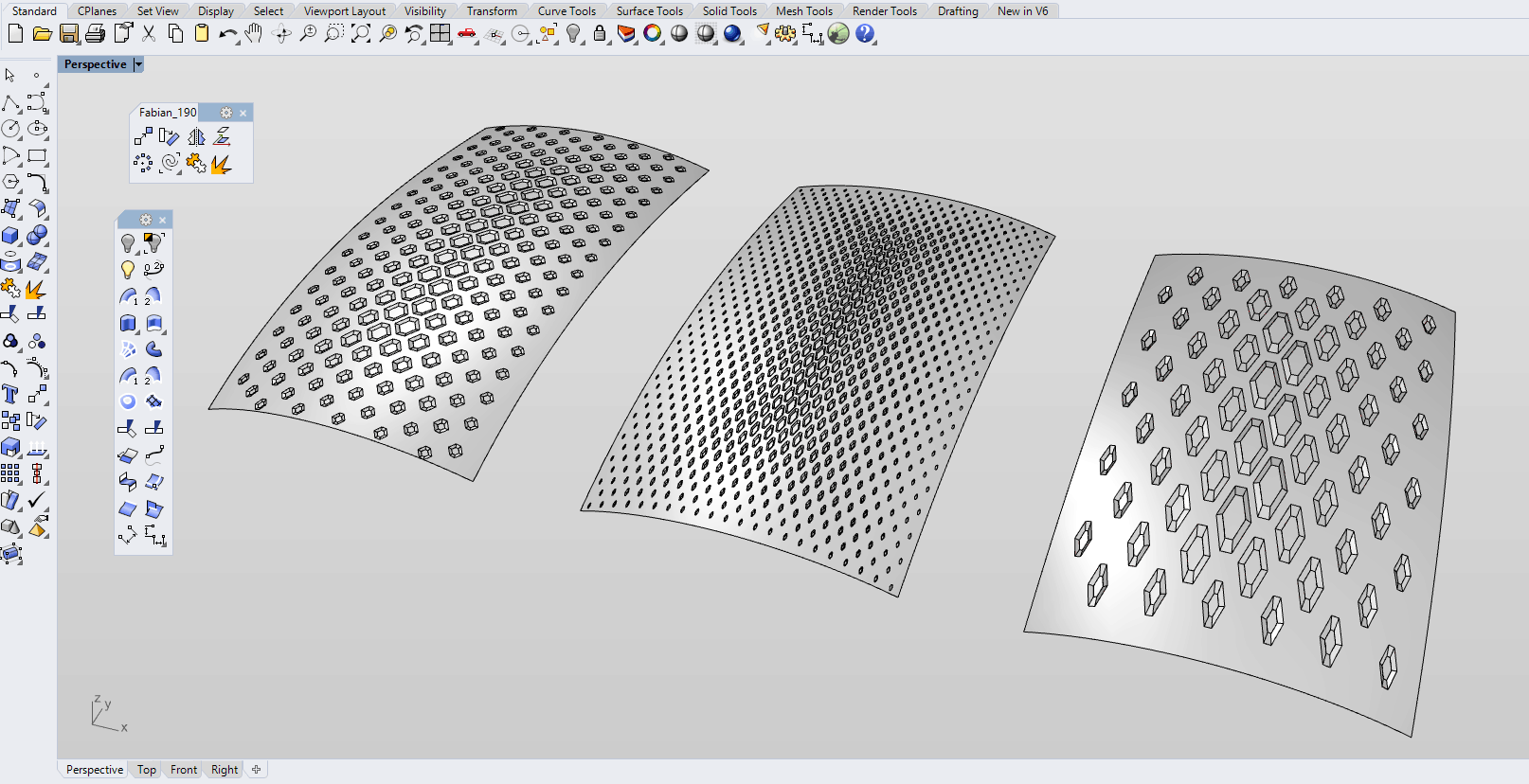

Create an eye-catcher with a uniquely beautiful material surface and a fascinating pattern that skilfully plays with light and shadow!

Upgrade existing products with the generative design technique!

Refine your products!

Be unique!

Be a pioneer!

The creation of patterns and surface structures...

...is probably the parade discipline of generative design. Nobody can or wants to build a geometrically perfect or even random surface structure consisting of the smallest elements by hand.

A simple body can become unique and unmistakable with a parametrically processed surface. Once the function for the desired pattern has been created, it can be applied to almost all surfaces in your product line and modified as desired.