What is necessary for sustainable product development?

sustainability is the challenge of our time. For long-term economic success, we can no longer do without a clear focus and the integration of ecological strategies. Regulatory interventions by government officials and ethical-ecological purchasing decisions by consumers and investors will find their way into all areas of the market.

With regard to design and development, what could be the criteria or principles that sustainable design is based on?

According to studies, 80% of the environmental impact and costs of a product are determined by the design (W. Hopfenbeck, C. Jasch: Eco-Design. Environmentally oriented product policy. Modern Industry, Landsberg/Lech 1995, p. 128). Subsequent changes to manufacturing locations, materials or packaging and supply chains will have far less impact if they are not planned from the ground up and fixed in the design. It is therefore best to start early when planning a sustainable product strategy.

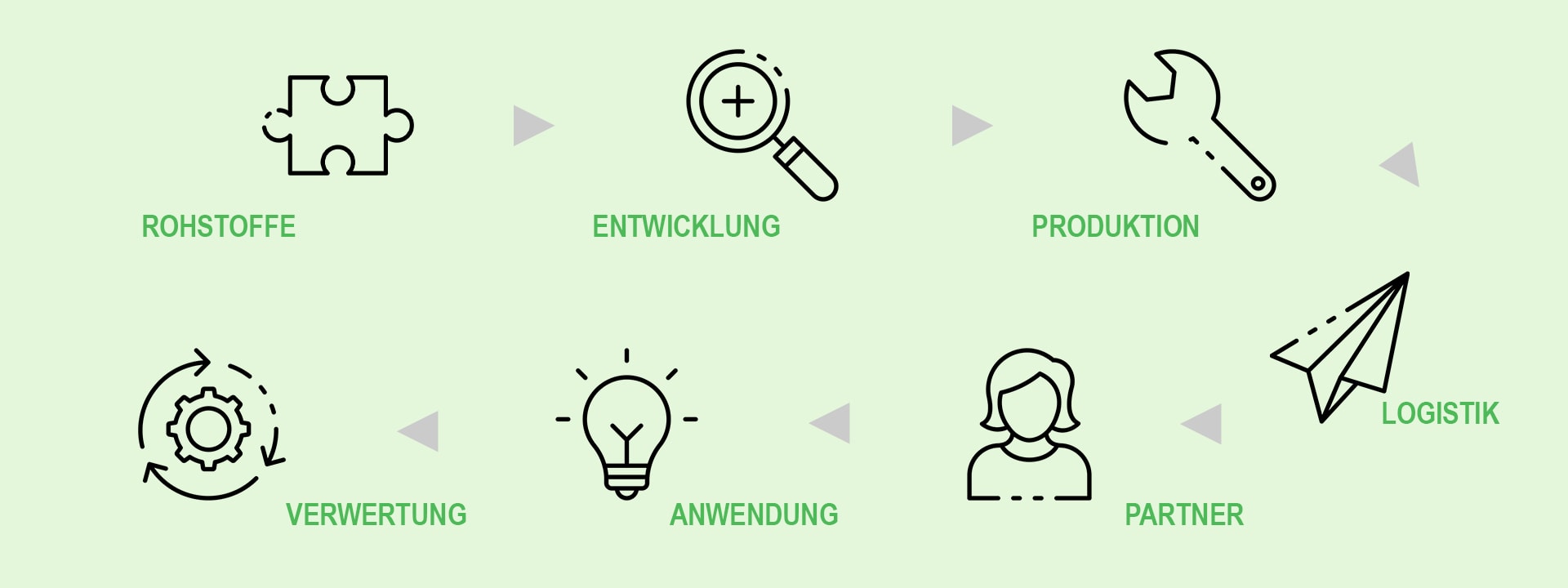

We support you with our methods of sustainable product development and integrate the necessary measures and concepts into every stage of the design process. Transparency in development and production, documentation of the results and a good information policy increase the credibility of the brand.

Principles for sustainable design and production

At its core, it is about intelligent use of the available resources for the greatest possible benefit for all actors involved. The environment should not be unnecessarily burdened and fair social conditions should be ensured. So that a secure economic basis is created.

Common criteria are:

- long life cycles

- Economical & material-appropriate use of resources

- resource-saving, low-emission materials

- low energy consumption in production

- environmentally friendly logistics and supply chains

- waste-avoiding production

- repairability

- recyclability

- easy disposal

Holistic, ecological thinking poses many challenges in everyday life and can only rarely be implemented with the requirements for products and services. Because the various players in the value chain have very different priorities and requirements. At first glance, purely economic and profit-oriented approaches often conflict with environmental considerations.

In most cases, these apparent contradictions can be refuted by new solutions. With a precise and unbiased view of the product and market requirements, innovative and disruptive approaches allow new, successful paths to be taken in product development. Ecological and economic sustainability are the common goal.

In us you will find the right partner for this challenging task.

Since we have a direct influence on the design of the products, we can have an influence right from the beginning of the planning, through the conception and design to production and logistics. Shape, ergonomics and application connect technology with users.

Use our experience to exploit all possible potentials in production. In the best case, we accompany the entire process and keep an eye on the overall concept. Reasonable, holistically thought-out products not only make your company future-proof, but also make a valuable contribution to the preservation of living environments.

How can these criteria be implemented?

Using the example of the BlueLavage, we explain a sustainable approach to our design. The project is a particularly successful case, as particularly high hygiene and material requirements in medical technology make sustainable solutions difficult.

The BlueLavage suction and irrigation system for tissue cleaning during surgical procedures is a completely new type of resource-efficient unit in the field of medical technology. The system flushes bone and tissue particles, bacteria and foreign material out of the wound and continuously aspirates them.

Our partner UTK Solutions came to us with the idea of a product innovation. The product should be rethought so that components can be reused and the amount of waste generated is reduced. Around 49% of the plastic and electronic parts to be disposed of can be saved in this way.

In Germany alone, around 434,000 flushing systems are used in operating theaters every year. These are completely disposed of after use. Disposable products are indispensable for hygiene reasons in the medical field. However, the annual consumption of around 334 t of plastic, 2.6 million batteries and 434,000 motors is far too resource-intensive for this product alone.

The innovative separation of the BlueLavage into a single-use handpiece and a reusable drive unit with patented locking leads to a significant improvement in sustainable production and use compared to conventional solutions.

The necessary sterility requirements are met by a packaging concept with an ergonomic insertion funnel. The funnel enables the drive unit to be inserted hygienically during the operation. The motor and batteries of the wound irrigation system can be reused up to 150 times.

The product has already received an award for this achievement.

In 2019 it was with the Efficiency Award NRW honored.

In 2021 we could already sign up for the Final jury of the IF Design Awards to qualify.

Conclusion

In view of the successful results of this project, it can be said in summary that economy and ecology can be combined.

Opportunities often have to be shown first, which means that it is necessary to network across disciplines and allow alternative solutions.

In us you will find a competent, innovation-driving partner. Benefit from our internal know-how, interdisciplinary network and, last but not least, from our motivation to shape progress together.